First class equipment

Providing OEM / ODM services

Ultra low temperature ethanol extraction

Good after-sales service

ABOUT

PIONEER EXTRACTION SOLUTION

Pioneer extraction solution is a U.S. - based company that manufactures medical herb/essential extraction machines and other herbal extraction machines

Pioneer extraction solution is dedicated to reduce the labor-intensive process of medical herb/other herb extraction, and help you extract high-quality oil from hemp/cannabis in the most efficient and safe way.

We believe that you will choose us firmly in the future

The equipment can also be equipped with automatic feeding, decolorization, remove pesticide residues, remove heavy metals, solvent distillation functions according to customers needs.

In a word all of our machines can be customized according to the different needs of each customer.

Besides, good after-sales service is also one of our feature. Our after-sales department is on-line 24 hours a day, which can eliminate faults and solve problems as quickly as possible.

OUR BEST

PRODUCTS

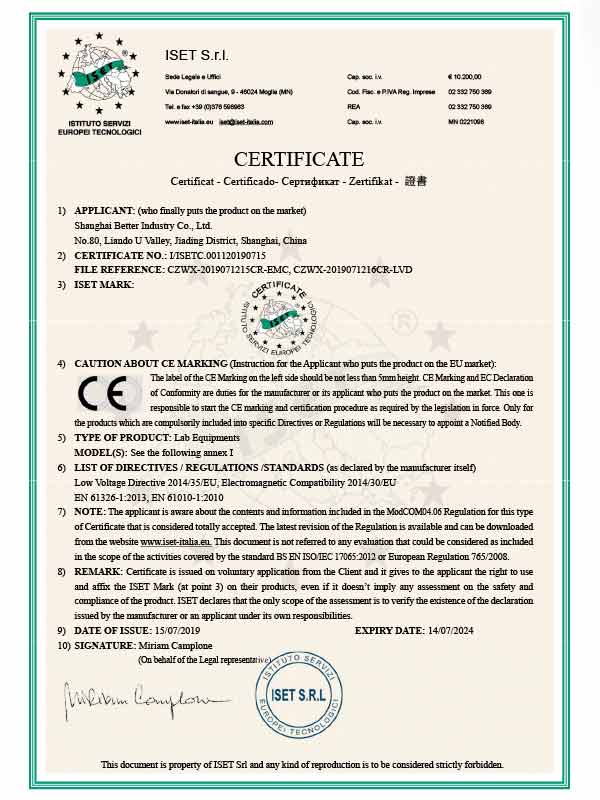

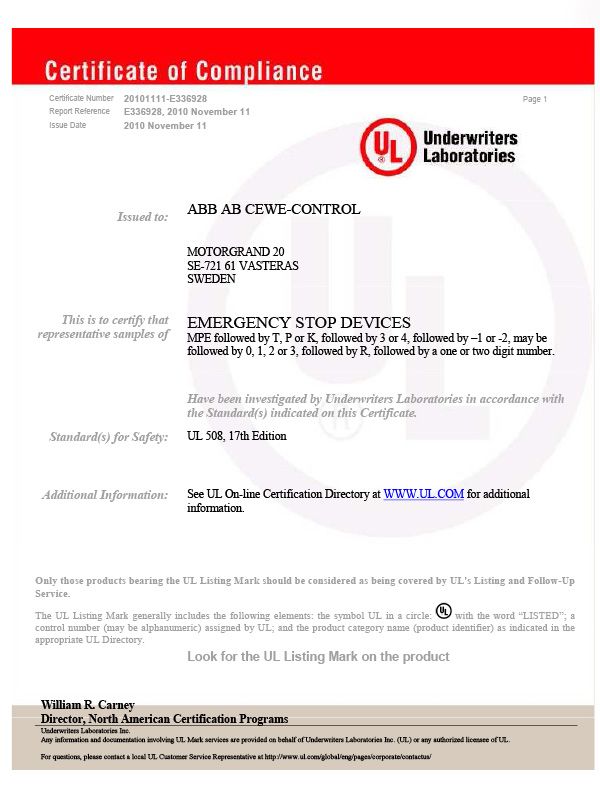

OUR

CERTIFICATES

LATEST

EVALUATION

DETAILED PRODUCT VIDEO

EXPLANATION

Low Temperature Ethanol Extraction Machine

Supercritical Co2 Extraction Machine

Winterization Machine

Laboratory Equipment

Ultrasonic Solvent Extraction And Concentration Machine

Essential Oil Extraction Machine

English

English